8 Steps in PCB Manufacturing

Table of Contents

- Introduction

- What is PCB Manufacturing?

-

Key Types of PCBs

- 3.1 Rigid PCBs

- 3.2 Flexible PCBs

- 3.3 Rigid-Flex PCBs

- 3.4 HDI (High-Density Interconnect) PCBs

-

The Steps in PCB Manufacturing

- 4.1 Design and Layout

- 4.2 Material Selection

- 4.3 PCB Etching

- 4.4 Drilling and Hole Creation

- 4.5 Lamination

- 4.6 Solder Mask and Surface Finish

- 4.7 Assembly and Mounting

- 4.8 Testing and Quality Control

-

Advanced PCB Manufacturing Techniques

- 5.1 Microvia Technology

- 5.2 ELIC (Every Layer Interconnect) PCB

- 5.3 Rapid Prototyping and Quick Turn PCB

-

Why Choose Wintech for PCB Manufacturing?

- 6.1 PCB Design and Layout Services

- 6.2 High-Quality Mass Production

- 6.3 Flexibility and Customization Options

-

FAQ

- 7.1 What is the difference between HDI and traditional PCBs?

- 7.2 How long does it take to manufacture a PCB prototype?

- 7.3 What is the cost range for PCB manufacturing in China?

- Conclusion

1. Introduction

Printed Circuit Boards (PCBs) are the backbone of modern electronics, serving as the critical interface that connects and supports electronic components in devices ranging from smartphones to medical equipment. The manufacturing process of PCBs is a highly specialized field that requires precision, advanced technology, and attention to detail. This guide takes you through the essential steps involved in PCB manufacturing, exploring the various techniques and types of PCBs that are used today.

Wintech, one of the leading PCB manufacturers in China, specializes in a wide range of PCBs, from basic designs to complex multilayer boards. With over 70 layers and technologies like HDI, rigid-flex, and flexible circuits, Wintech offers high-quality PCB fabrication and assembly services that cater to various industries worldwide.

2. What is PCB Manufacturing?

PCB manufacturing is the process of creating the physical board that connects and supports electronic components through conductive pathways. It involves several stages, including design, material selection, etching, drilling, lamination, soldering, and testing. Depending on the complexity of the design, additional processes like microvia creation, surface finishing, and assembly may also be included.

At Wintech, we offer a comprehensive range of PCB solutions, from basic single-layer boards to advanced HDI (High-Density Interconnect) boards and flexible circuits. Our services cover every step, including PCB design, layout, assembly, rapid prototyping, and mass manufacturing.

3. Key Types of PCBs

Before delving into the steps of PCB manufacturing, it’s important to understand the different types of PCBs available. The type of PCB you choose will directly impact the design, materials, and manufacturing process.

3.1 Rigid PCBs

Rigid PCBs are the most commonly used boards in consumer electronics. As the name suggests, these boards are made from solid, rigid materials, offering durability and stability. They are ideal for applications where high performance and reliability are required.

3.2 Flexible PCBs

Flexible PCBs are designed to be flexible and can be bent or folded without affecting their functionality. These boards are used in applications like wearable electronics, medical devices, and automotive components.

3.3 Rigid-Flex PCBs

Rigid-flex boards combine both rigid and flexible circuits on the same board, offering the advantages of both types. These boards are used in applications where space is limited and flexibility is needed, such as in aerospace and mobile devices.

3.4 HDI (High-Density Interconnect) PCBs

HDI PCBs are high-performance boards that incorporate advanced techniques like microvia and fine-pitch technologies. These boards are used in applications requiring high speed, high frequency, and compact designs, such as in smartphones and computers.

4. The Steps in PCB Manufacturing

PCB manufacturing is a multi-step process that involves precision and accuracy at every stage. Below is an overview of the key steps involved in creating a PCB.

4.1 Design and Layout

The first step in PCB manufacturing is designing the circuit and layout. This involves creating a schematic diagram of the circuit, choosing components, and determining the arrangement of components on the board. PCB designers use specialized software tools like Altium Designer or Eagle to create the layout.

At Wintech, we offer comprehensive PCB design and layout services to ensure that your design is optimized for manufacturability, cost efficiency, and performance.

4.2 Material Selection

Choosing the right materials is crucial for the performance of the PCB. The base material for most PCBs is usually fiberglass (FR4), but for specialized boards like flexible PCBs, materials such as polyimide are used. For high-frequency applications like RF circuits, materials like PTFE (Teflon) are selected.

Wintech offers a variety of high-quality materials suitable for different types of PCBs, including multilayer rigid PCBs, HDI PCBs, and rigid-flex PCBs.

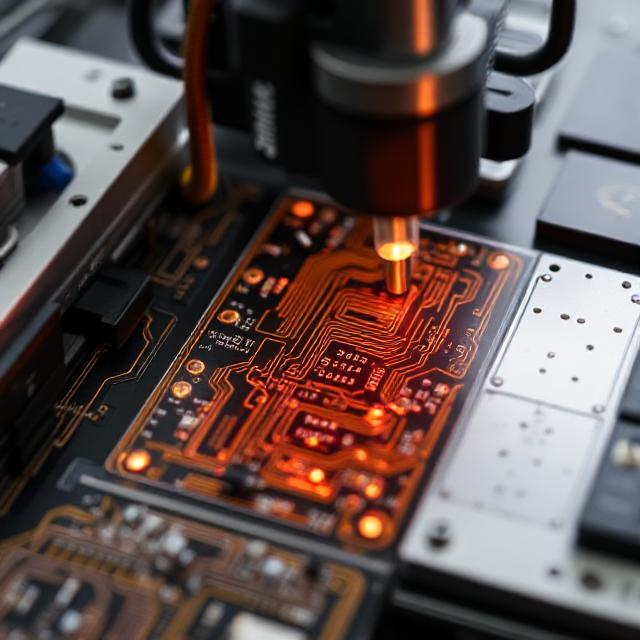

4.3 PCB Etching

PCB etching is a process where unwanted copper is removed from the board, leaving behind the desired conductive pathways. This is usually done through a chemical etching process, where the PCB is exposed to a chemical solution that dissolves the unwanted copper.

4.4 Drilling and Hole Creation

Drilling is an essential step for creating vias (holes) that connect different layers of the PCB. Depending on the design, this can involve drilling small holes for through-hole components or creating microvias for high-density designs. The size of the holes can range from standard sizes for traditional components to microvias for HDI and flexible circuits.

4.5 Lamination

For multilayer PCBs, the next step is lamination. This involves stacking the individual layers of the PCB and bonding them together under heat and pressure. The lamination process is crucial for ensuring the integrity of the board’s electrical and mechanical properties.

4.6 Solder Mask and Surface Finish

The solder mask is applied to the PCB to protect the copper traces and prevent short circuits. After the solder mask is applied, a surface finish is added to the pads to prepare them for soldering. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

4.7 Assembly and Mounting

Once the PCB is fabricated, it’s time to assemble the components. This is where the components are soldered onto the board. This step can be done manually or through automated processes like SMT (Surface-Mount Technology).

Wintech offers PCB assembly and PCBA SMT services, ensuring that each component is accurately placed and soldered for maximum performance and reliability.

4.8 Testing and Quality Control

Finally, the finished PCB undergoes rigorous testing to ensure that it meets the required performance and reliability standards. This includes electrical testing, visual inspection, and sometimes functional testing, depending on the complexity of the PCB.

At Wintech, we emphasize quality control at every stage of the PCB manufacturing process. We use advanced testing methods to ensure that every PCB meets the highest standards of quality.

5. Advanced PCB Manufacturing Techniques

5.1 Microvia Technology

Microvia technology is used in HDI PCBs and allows for the creation of very small holes (vias) that enable higher density interconnects. This is crucial for compact designs in modern electronics.

5.2 ELIC (Every Layer Interconnect) PCB

ELIC technology is used in multi-layer PCBs to create electrical connections between layers without needing vias. This method is often used in high-speed and high-frequency applications.

5.3 Rapid Prototyping and Quick Turn PCB

For new products, rapid prototyping is essential. Quick turn PCB services, such as those offered by Wintech, allow for fast delivery of prototype PCBs, which speeds up the design iteration process and reduces time-to-market.

6. Why Choose Wintech for PCB Manufacturing?

6.1 PCB Design and Layout Services

Wintech provides end-to-end PCB design and layout services, ensuring that your design is optimized for manufacturability and cost-effectiveness.

6.2 High-Quality Mass Production

We offer mass production capabilities, from 2-layer to 70-layer PCBs, with fast turnaround times and high-quality manufacturing.

6.3 Flexibility and Customization Options

Whether you need a simple single-layer board or a complex HDI, rigid-flex, or FPC board, Wintech can customize your PCB to meet the unique needs of your project.

7. FAQ

7.1 What is the difference between HDI and traditional PCBs?

HDI PCBs use smaller vias and more layers than traditional PCBs, allowing for higher component density and more compact designs. They are ideal for applications where space, performance, and speed are crucial.

7.2 How long does it take to manufacture a PCB prototype?

PCB prototypes can typically be manufactured in 3-7 days, depending on the complexity of the design

and the materials required.

7.3 What is the cost range for PCB manufacturing in China?

The cost of PCB manufacturing can vary greatly depending on factors like complexity, quantity, and materials. Prices typically range from $1 to $10 per unit for basic designs, while more complex boards can cost more.

8. Conclusion

PCB manufacturing is a detailed and intricate process that requires precision and expertise. Whether you need basic single-layer boards or advanced multilayer designs like HDI and rigid-flex, Wintech offers high-quality PCB manufacturing services. With a commitment to innovation and quality control, Wintech ensures that each PCB meets your specifications and performs reliably in your applications. From rapid prototyping to mass production, we provide the solutions you need to bring your products to life.