Quality Assurance

Zero-defect tolerance is our business strategy. We strive to design products aligned with the Design for Excellence concept to eliminate any root causes. Prior to the mass production, every product is thoroughly verified and tested against any functional and operational integrated failures according to industry-recognized quality standards and certifications. Real-time monitoring over the entire production process ensures you get a reliable product in compliance with a design and manufacturing specification.

Our desire to deliver world class manufacturing solutions and total customer satisfaction is the driving force behind our Quality Assurance policies and procedures.these combine to deliver high reliability products, in accordance with our customers specifications, on time, in full,at a competitive price.

Quality controls and compliance tests are integrated throughout the Wintech Technology production process. With on-going staff training and a corporate culture committed to excellence, we are able to deliver total vertical contract manufacturing services with low costs and unmatched reliability.

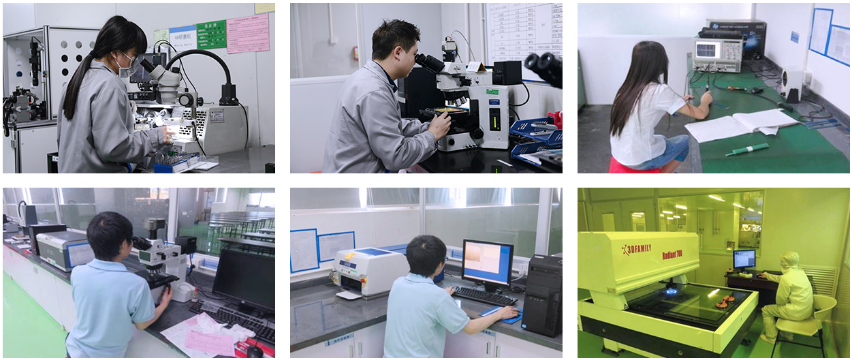

Wintech Technology has invested in state-of-the-art inspection equipment, and performs quality tests and compliance checks throughout our manufacturing operations. Some of our testing and QC processes include:

• 3D printing for design evaluation & validation

• Automatic optical inspection (AOI)

• Burn-in testing

• Functional testing

• In-circuit testing (ICT)

• Spectral bandwidth inspection using spectrophotometers

• Temperature-controlled cycling burn-in testing (-40°C to +150°C)

• X-ray inspection – via an x-ray viewer and RoHS scanning equipment

• Serializing and labeling to complete box build

• MES traceability management system

Contract Manufacturing & Compliance Testing for Global Applications

With well-controlled processes and an experienced team, Wintech Technology has integrated QC and QA checks throughout our manufacturing operations. Our quality processes comply with extremely strict standards, and meet even the most demanding customer's requirements.

Our leading electronics contract manufacturing services ensure components and products comply with the Restriction of Hazardous Substances (RoHS) and EU REACH requirements along with globally-recognized standards and recommendations.