Is It Cheaper to Make Your Own PCB?

Title: Is It Cheaper to Make Your Own PCB? A Comprehensive Guide for 2025

Table of Contents

- Introduction: Understanding PCB Manufacturing

-

The Cost Factors of PCB Production

- 1. Material Costs

- 2. Labor and Skill Requirements

- 3. Equipment and Tools

- Advantages of Making Your Own PCB

- Disadvantages of Making Your Own PCB

-

Why You Might Consider Professional PCB Manufacturers

- 1. Wintech's Turnkey PCB Solutions

- Frequently Asked Questions (FAQs)

- Conclusion: Is DIY PCB Manufacturing Worth It?

1. Introduction: Understanding PCB Manufacturing

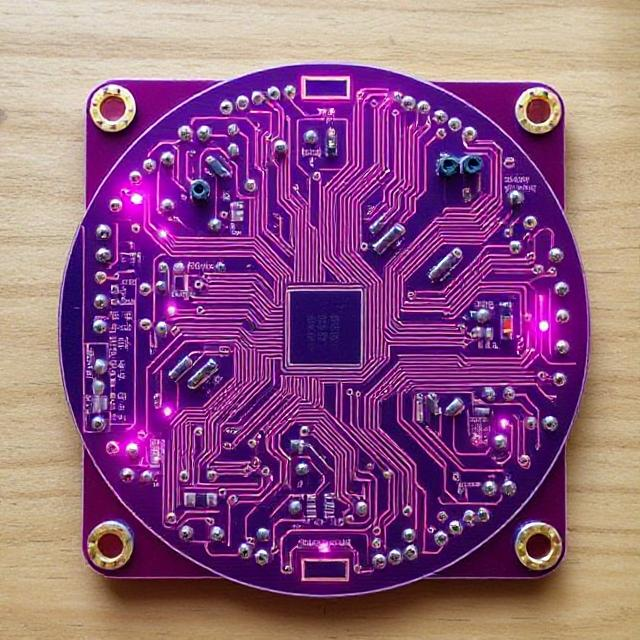

Printed Circuit Boards (PCBs) are the backbone of most electronic devices today, from smartphones and computers to industrial machinery. The demand for custom-designed PCBs is increasing, as more businesses are opting for tailored solutions to meet their specific needs. However, an important question often arises: Is it cheaper to make your own PCB, or should you outsource the process to a professional manufacturer?

In this article, we will explore the factors that influence the cost of PCB production, compare the benefits and drawbacks of making your own PCBs versus outsourcing the task, and help you determine which approach is more cost-effective for your business in 2025.

2. The Cost Factors of PCB Production

When deciding whether to manufacture PCBs in-house or outsource, understanding the various cost factors is crucial. PCB manufacturing is not just about the cost of the components; several other expenses come into play. Below, we break down the key cost factors.

1. Material Costs

The material cost of a PCB consists of the base substrate (usually fiberglass), copper foil, solder mask, and silkscreen. Depending on the complexity and specifications, the material costs can vary significantly.

In-house Manufacturing:

- Material Sourcing: You need to source raw materials, which can be difficult and expensive if you do not have established relationships with suppliers.

- Bulk Purchase: In-house production may make sense for high volumes, as buying materials in bulk can reduce overall costs.

Outsourcing:

- Pre-negotiated Rates: Professional PCB manufacturers often buy materials in bulk, which can help reduce overall material costs.

- Material Selection: Outsourcing manufacturers can provide a wider range of materials tailored to specific applications, such as high-temperature or flexible PCBs.

2. Labor and Skill Requirements

Manufacturing PCBs requires highly skilled workers who are trained in the nuances of PCB design, layout, and assembly. Without the right expertise, your DIY PCB may not function as expected.

In-house Manufacturing:

- Skilled Labor: You must either hire or train employees to handle tasks such as PCB design, soldering, and assembly.

- Time Investment: The process of prototyping and troubleshooting can take a significant amount of time, especially if you lack experience.

Outsourcing:

- Experienced Workforce: Professional PCB manufacturers employ skilled engineers and technicians who can handle complex tasks efficiently.

- Reduced Risk: With experts on hand, there is a reduced risk of design errors or faulty assembly.

3. Equipment and Tools

Manufacturing your own PCB requires specialized equipment, including PCB printers, soldering stations, etching tanks, and more. This equipment can be expensive, and maintenance costs can add up over time.

In-house Manufacturing:

- Initial Investment: Setting up your own PCB manufacturing facility requires substantial capital investment in equipment and facilities.

- Ongoing Maintenance: Regular maintenance of the equipment is required to ensure its functionality, adding additional ongoing costs.

Outsourcing:

- No Equipment Cost: When outsourcing, you don’t need to worry about the cost of acquiring or maintaining specialized equipment.

- Up-to-date Technology: Professional manufacturers often use cutting-edge equipment, which can lead to higher quality and more efficient production.

3. Advantages of Making Your Own PCB

For some businesses, manufacturing PCBs in-house offers several advantages, particularly in terms of control and flexibility.

1. Full Control Over the Design Process

By manufacturing your own PCBs, you have full control over the entire design and production process. This can be beneficial if your project has specific requirements that may be difficult to communicate to a third-party manufacturer.

2. Faster Prototyping

In-house production can speed up the prototyping process, as you do not have to wait for an external manufacturer to produce your PCB. This is especially advantageous if you need quick iterations for testing or development.

3. No Minimum Order Quantities

Many PCB manufacturers have minimum order quantities (MOQs), which may not be cost-effective if you are working on small-scale projects or prototypes. Manufacturing in-house eliminates this limitation.

4. Disadvantages of Making Your Own PCB

While there are benefits, there are also significant challenges to consider when deciding to manufacture your own PCBs.

1. High Initial Costs

Setting up a PCB manufacturing facility requires significant capital investment in equipment and tools. For small to mid-sized businesses, these costs may be prohibitive.

2. Limited Scalability

In-house PCB production may not be suitable for scaling up production, especially if your needs change over time. Professional PCB manufacturers have the infrastructure to handle high-volume production efficiently.

3. Time-Consuming

PCB manufacturing is a complex and time-consuming process. From design to assembly, it can take days or even weeks to complete a single batch. Outsourcing allows you to focus on other aspects of your business while leaving PCB production to the experts.

5. Why You Might Consider Professional PCB Manufacturers

While making your own PCBs might seem cost-effective in some cases, professional PCB manufacturers offer several advantages that can make outsourcing the better choice for many businesses.

1. Wintech's Turnkey PCB Solutions

Wintech provides full turnkey services, including PCB design and layout, manufacturing, assembly, and even prototyping. This end-to-end solution simplifies the process for businesses by handling all aspects of PCB production, from concept to finished product.

Why Choose Wintech?

- High Precision PCB Layouts: Wintech specializes in creating high-level, precise PCB layouts, even for complex and large-sized projects.

- Low to Mid-Volume Production: Whether you’re a startup or an established business, Wintech can handle both low and mid-volume PCB production efficiently.

- Customized Solutions: Wintech offers tailored PCB solutions for specific customer needs, ensuring that your project requirements are met with the highest quality standards.

By outsourcing to a trusted partner like Wintech, you can avoid the costs and challenges of in-house PCB manufacturing while ensuring that your PCBs are produced using the latest technologies and techniques.

6. Frequently Asked Questions (FAQs)

Q1: Is it really cheaper to make your own PCBs?

A1: The cost-effectiveness of in-house PCB manufacturing depends on factors such as the scale of production, equipment costs, and labor. While small-scale DIY production may be cheaper initially, the long-term costs of equipment, material sourcing, and maintenance often make outsourcing to professional manufacturers like Wintech more cost-effective for larger volumes.

Q2: What is a PCB turnkey solution?

A2: A PCB turnkey solution is a complete service that includes everything from PCB design and layout to manufacturing and assembly. Professional manufacturers like Wintech offer turnkey solutions, simplifying the process for businesses by handling every aspect of PCB production.

Q3: How do I know if outsourcing PCB manufacturing is the right choice for my business?

A3: If you require high-quality, large-scale production with fast turnaround times, outsourcing is usually the best option. It is especially beneficial if you lack the expertise, equipment, or time to handle the complexities of PCB manufacturing in-house.

7. Conclusion: Is DIY PCB Manufacturing Worth It?

While making your own PCBs might seem like a good idea for small, simple projects, the reality is that professional PCB manufacturing often proves to be more cost-effective in the long run. The initial investment in equipment, the complexity of PCB design, and the need for skilled labor make in-house production a significant challenge for most businesses.

Wintech’s comprehensive turnkey solutions provide businesses with high-quality, efficient, and cost-effective alternatives to in-house PCB manufacturing. Whether you need prototyping, low to mid-volume production, or high-precision PCBs, outsourcing to a trusted manufacturer like Wintech is often the best choice for businesses looking to scale and focus on their core operations.

| Factors to Consider | In-house Manufacturing | Outsourcing to Professionals |

|---|---|---|

| Initial Investment | High | Low |

| Labor Requirements | High | Low |

| Time to Production | Long | Short |

| Customization | High | High (with experts) |

| Scalability | Limited | High |

| Cost for Prototyping | Low | Moderate |

Making the right decision will depend on your specific needs, but for most businesses, outsourcing PCB production to professional manufacturers like Wintech offers a more efficient, cost-effective solution.