5 Best PCB Board Fabrication Software in 2025

Table of Contents

- Introduction: What is PCB Board Fabrication Software?

- Why PCB Design Software is Essential for Manufacturers

-

Top 5 PCB Fabrication Software in 2025

- 3.1 Altium Designer

- 3.2 EAGLE PCB Design Software

- 3.3 KiCad

- 3.4 Autodesk Fusion 360

- 3.5 Proteus PCB Design

- Key Features to Look for in PCB Fabrication Software

- Wintech PCB Assembly: A Reliable PCB Manufacturing Partner

- Common PCB Design Challenges and Solutions

- Frequently Asked Questions (FAQs)

- Conclusion: Choosing the Right PCB Fabrication Software

Introduction: What is PCB Board Fabrication Software?

Printed Circuit Boards (PCBs) are at the heart of nearly all electronic devices. They provide the physical platform for electronic components to connect and communicate. The process of designing and fabricating a PCB requires specialized software that can help engineers with creating the layout, testing the design, and ensuring that the board meets various electrical and manufacturing standards. This article explores some of the top PCB fabrication software available in 2025, their features, and how to choose the best one for your needs.

Why PCB Design Software is Essential for Manufacturers

PCB design software has become an essential tool for manufacturers and engineers, enabling the precise creation of designs for electronics that will be mass-produced. The software allows engineers to simulate the electrical functions, test for errors, and produce designs that can be directly used for fabrication. In addition, these tools help reduce human error, speed up the design process, and ensure that the final product meets the strict requirements of quality standards, such as military and medical-grade certifications.

Key reasons why PCB design software is crucial:

- Accuracy: Software tools ensure precision in the design, which is vital for high-performance applications.

- Automation: Modern PCB software often includes automation features that can speed up various parts of the design process, such as component placement and routing.

- Collaboration: Many PCB design tools offer cloud-based or collaborative features to enable teams to work together, even across different locations.

- Cost-Effective Prototyping: Software tools can simulate PCB designs before physical prototyping, helping to reduce costs and time for testing.

Top 5 PCB Fabrication Software in 2025

Choosing the right PCB board fabrication software can depend on various factors, including the complexity of the PCB design, the industry standards required, and the level of support you need. Here are the top 5 PCB design software options in 2025:

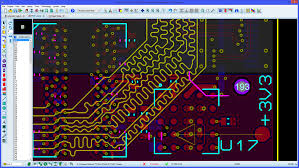

3.1 Altium Designer

Altium Designer is one of the most popular and powerful PCB design software solutions available today. Known for its user-friendly interface and robust feature set, it is widely used by professionals in high-tech industries, including aerospace, medical, and automotive.

Key Features:

- Unified Design Environment: Altium Designer integrates schematic capture, PCB layout, and PCB simulation into one platform.

- Advanced Routing Tools: Offers advanced routing tools such as differential pair routing, interactive routing, and auto-routing features.

- 3D Visualization: Provides 3D visualization of your designs to simulate real-world assembly and spot potential issues.

- Collaborative Design: Allows team members to work on the same design in real-time, improving efficiency.

Best for: Large-scale projects and enterprises needing high-level PCB design and assembly.

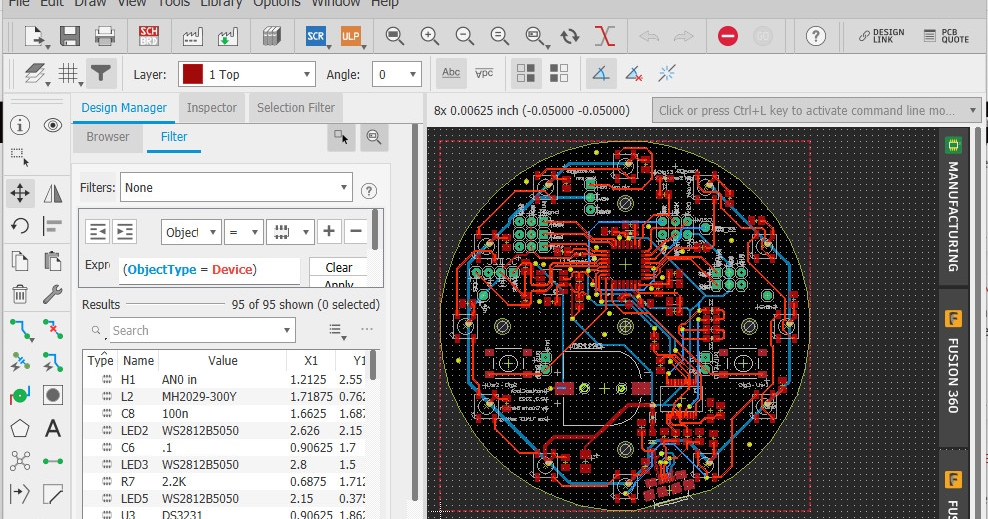

3.2 EAGLE PCB Design Software

Autodesk's EAGLE is another widely used PCB design software, especially for smaller-scale projects. It offers a feature-rich environment while maintaining an accessible learning curve, making it a favorite among startups, hobbyists, and educational institutions.

Key Features:

- Schematic Editor: Includes a powerful schematic editor with built-in libraries and tools for creating custom components.

- Board Layout: Features a PCB board layout editor that is simple to use but flexible enough to handle complex designs.

- Component Libraries: Provides access to an extensive library of components to streamline the design process.

- Auto-Routing: Includes an auto-routing function for quickly connecting components.

Best for: Small to medium-sized businesses or hobbyists looking for an affordable yet comprehensive solution.

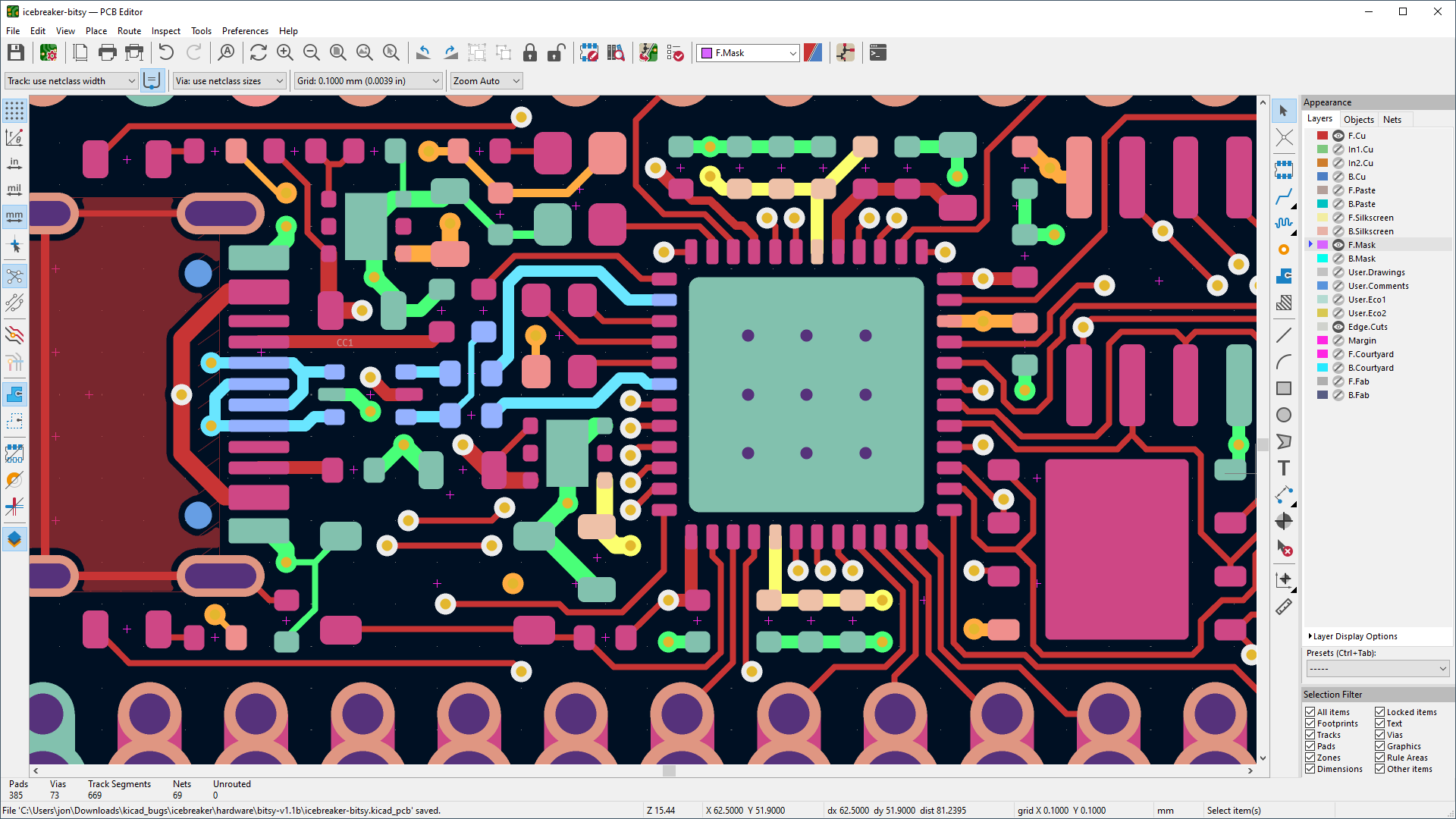

3.3 KiCad

KiCad is a free and open-source PCB design tool that has gained popularity for its powerful capabilities and active developer community. It’s suitable for both professionals and amateurs, offering a complete suite of tools for PCB design and fabrication.

Key Features:

- Free and Open-Source: KiCad is free to use and has no restrictions on the number of layers or components.

- Comprehensive Design Tools: Offers tools for schematic capture, PCB layout, and 3D visualization.

- Customizable: Users can create custom components and footprints, which is a key advantage for unique or specialized designs.

- Community Support: Extensive online community and resources for troubleshooting and learning.

Best for: Hobbyists, educational users, or small companies with a tight budget but requiring a professional-level tool.

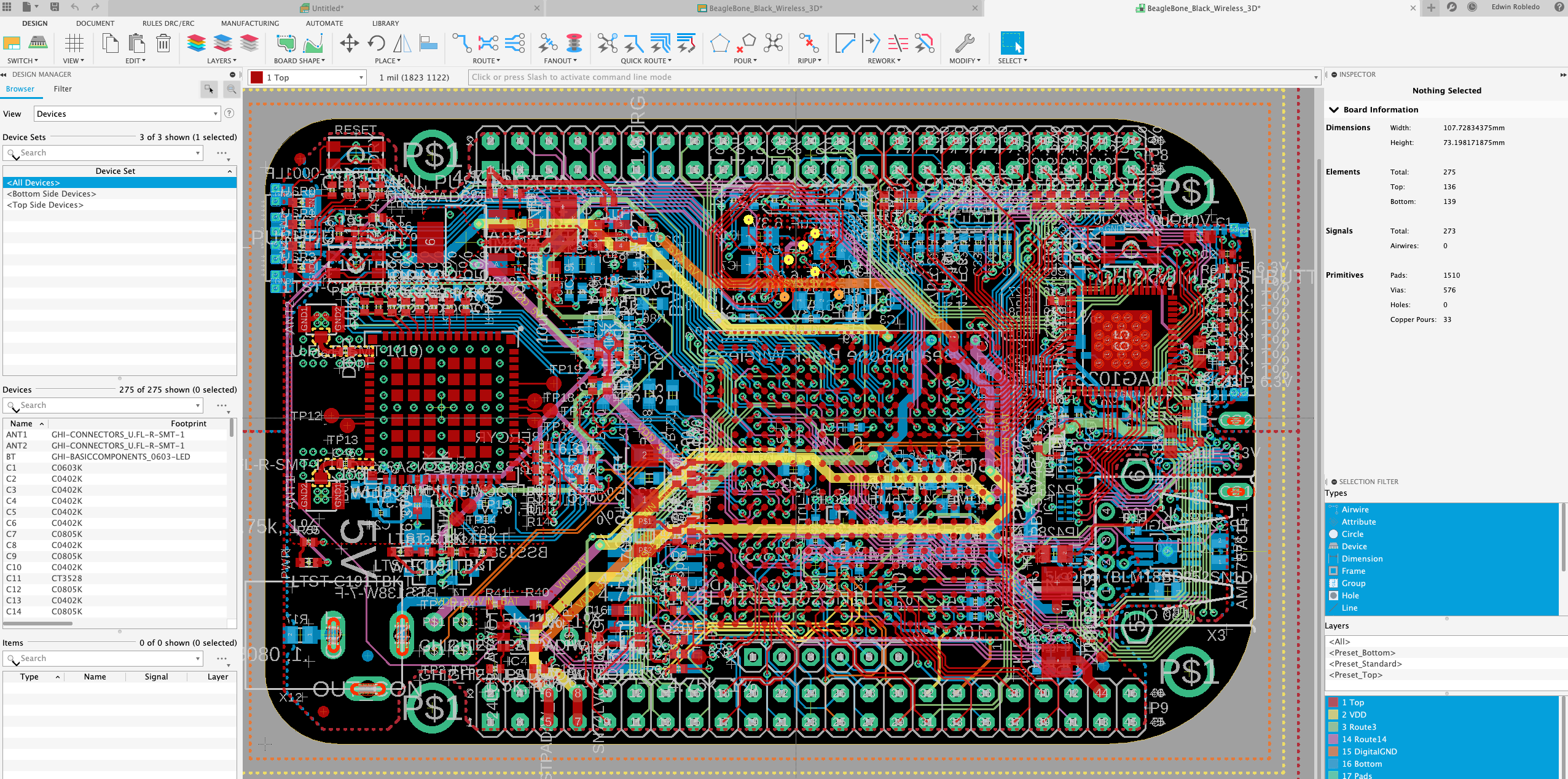

3.4 Autodesk Fusion 360

Autodesk Fusion 360 is a cloud-based software that integrates design, engineering, and manufacturing in a single platform. While it’s often used for mechanical design, it’s also increasingly popular in the electronics space, particularly for PCB design.

Key Features:

- Integrated CAD and PCB Design: Fusion 360 combines CAD and PCB design tools in one platform, allowing seamless transitions between mechanical and electrical design.

- 3D Modeling: Features a 3D modeler that can be used to simulate assembly and visualize components in a more realistic setting.

- Collaboration: Cloud-based design allows real-time collaboration with team members, making it ideal for distributed teams.

- Manufacturing Integration: Includes tools for manufacturing PCB designs directly from the software.

Best for: Teams requiring an all-in-one solution for both PCB and mechanical design.

3.5 Proteus PCB Design

Proteus is known for its excellent simulation capabilities, particularly for embedded system designers. It combines both schematic capture and PCB layout design in a single software package and is widely used in the academic and research sectors.

Key Features:

- Simulation: Proteus excels in circuit simulation, allowing users to test and debug designs before creating the physical board.

- Schematic Capture: Includes an intuitive schematic capture tool that integrates with the PCB layout editor.

- User-Friendly Interface: Offers an easy-to-use interface, ideal for both beginners and experienced engineers.

- Integrated Libraries: Provides access to a wide range of component libraries, which simplifies the design process.

Best for: Educational institutions and hobbyists working with embedded systems.

Key Features to Look for in PCB Fabrication Software

When choosing PCB fabrication software, consider these key features to ensure the software meets your needs:

- Ease of Use: The software should have an intuitive interface that helps users quickly adapt and navigate through different design stages.

- Simulation Tools: Effective simulation features allow you to test the design and identify potential issues before fabrication.

- 3D Visualization: Being able to visualize the design in 3D helps you better understand how the final product will look and interact.

- Collaboration Features: If you’re working with a team, collaboration features such as real-time editing, cloud-based access, and version control are crucial.

- Component Libraries: A comprehensive library of components can save a lot of time during the design phase.

- Advanced Routing Capabilities: Advanced routing tools ensure that your PCB will perform well and meet the required electrical specifications.

Wintech PCB Assembly: A Reliable PCB Manufacturing Partner

If you're looking for a reliable PCB assembly partner, Wintech PCB Assembly offers tailor-made solutions for high-level, complex, and high-precision PCB designs. Since its establishment, Wintech has built a reputation for its expertise in providing full turnkey services and high-quality electronics manufacturing solutions. Their services include:

- PCB Design & Layout: Wintech offers expert PCB design and layout services that meet military, medical, and other high-grade standards.

- PCB Assembly & PCBA SMT: With advanced surface-mount technology (SMT) and thorough quality checks, Wintech ensures the highest standards in PCB assembly.

- Quick Turnaround: They offer a 48-hour delivery service, ideal for rapid prototyping and low-to-mid volume production.

- Turnkey Manufacturing: From design to assembly to final product manufacturing, Wintech delivers a full-service solution for your PCB needs.

Whether you're working on prototypes, low-to-mid volume, or mass production, Wintech provides flexible, fast, and reliable services.

Common PCB Design Challenges and Solutions

-

Challenge 1: Signal Integrity Issues

Solution: Use advanced routing tools and simulation software to predict and mitigate signal issues

.

-

Challenge 2: Component Placement Constraints

Solution: Utilize software with intelligent component placement features to optimize space and improve efficiency. -

Challenge 3: Design Errors and Bugs

Solution: Use error-checking tools available in most PCB design software to catch mistakes before they lead to costly errors.

Frequently Asked Questions (FAQs)

Q1: Can I use free PCB software for professional PCB designs?

A1: Yes, many free software options like KiCad are capable of handling professional-level designs, especially for less complex projects.

Q2: How long does it take to learn PCB design software?

A2: The learning curve depends on the software you choose. While beginner tools like EAGLE are relatively easy to learn, more advanced software like Altium Designer may take a few months to master.

Q3: What is the cost of PCB fabrication software?

A3: The cost varies widely. Free options like KiCad are available, while professional software like Altium Designer or Autodesk Fusion 360 can cost hundreds to thousands of dollars annually depending on the package and features.

Conclusion: Choosing the Right PCB Fabrication Software

Selecting the right PCB fabrication software is crucial for ensuring that your designs are accurate, efficient, and manufacturable. Each software mentioned in this article has its strengths, so consider your project’s specific needs, such as the complexity of the design, simulation requirements, and budget. Whether you’re a professional in need of advanced features or a hobbyist looking for an accessible tool, there’s a PCB design solution for every need.